Zero Liquid Discharge solution

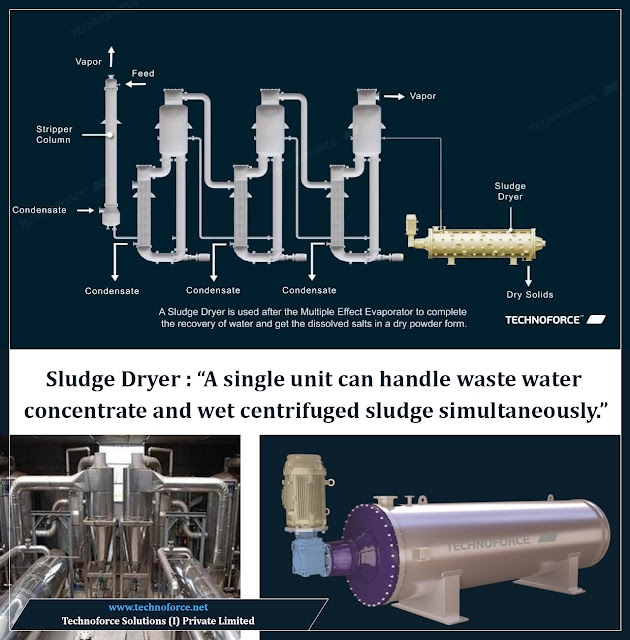

TechnoforcePvt.Ltd . Provide ZeroLiquid Discharge (ZLD) is a water treatment process in which all wastewater is decontaminated and reused; along these lines, leaving zero release toward the finish of the treatment cycle. Zero fluid release is a propelled wastewater treatment technique that incorporates ultrafiltration, invert assimilation, vanishing/crystallization, and partial electrodeionization. Aquatech has an unparalleled profundity of involvement in zero fluid release (ZLD), which incorporate in excess of 160 establishments, including remain solitary warm/evaporative procedures, film procedures, or half and half frameworks. Zero Liquid Discharge (ZLD) At a Glimpse -160 zero fluid release establishments on 6 landmasses -Trend-setters in Hybrid zero fluid release, combining layers, and warm evaporators -Dependable and financially savvy arrangements -Client support for long haul unwavering quality -Particular zero fluid release task and support administrat...